-

Foam Bladder Tank +

-

Foam Equipment

-

Foam Concentrate

-

Fire Monitor Series

-

Fire Hose & Cabinets

-

Landing Valve & Fire Hydrant

-

Fire Pump

-

Sprinkler & Spray Head

-

FM200 +

-

Fire Suit& Fire Extinguisher

-

Valves

-

Deluge Valve

-

Wet Alarm Valve

-

OS&Y Type Flanged End Gate Valve 200 PSI

-

OS&Y Type Grooved End Gate Valve 200 PSI

-

NRS Type Flanged Grooved Gate Valve With Round Plate 200 PSI

-

OS&Y Type Flanged Grooved End Gate Valve 200 PSI

-

NRS Type Flanged End Gate Valve 200 PSI

-

NRS Type Grooved End Gate Valve 200 PSI

-

Flanged End Swing Check Valve 300PSI

-

Wafer Type Butterfly Valve 300PSI

-

Grooved Type Butterfly Valve 300PSI

-

-

Dry Powder System +

Foam Bladder Tank

Foam Bladder Tank, Foam Tank for Firefighting

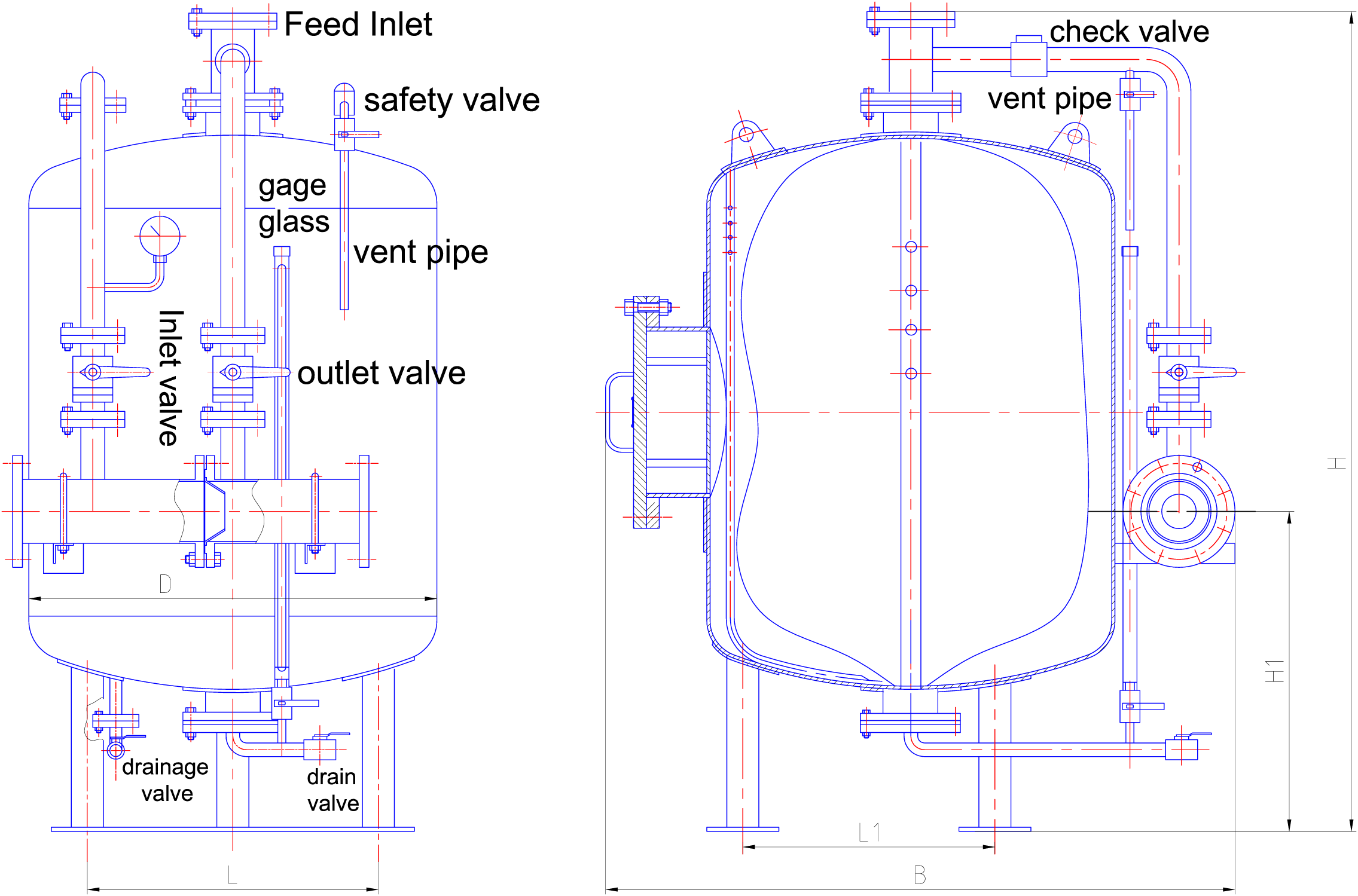

Product Introduction

The foam bladder tank is the main unit of the foam extinguishing system. The foam tank and the low/medium expansion foam generator construct the low/medium foam spraying system. It can also construct the high expansion total flooding extinguishing system with high expansion foam generator. It aims at fire of class A and class B, especially for fire of class B. The foam bladder tank mainly applied in occasions such as places where inflammable liquid was produced, stored and transported. It is especially suitable to put out fire caused by inflammable liquid tank or large scale of spill fire.

Structure and Principle

The device consists of pressure tank, bladder, proportioner, pressure gauge, valves and pipeline. A pump is needed to supply pressurized water. When pressurized water flow though proportioner, a small part of water (3%-6%) flow into tank from branch pipe to press the bladder to swap out equal foam concentrate and then mix with another part of water (97%-93%) to form foam solution in proportioner and provide to foam generator.

Characteristic:

1.Big flow pressure range and small pressure loss.

2.Widely used both in mid-multiples and low multiples foam extinguishing system.

3.Two types: horizontal and vertical.

Technical parameters:

|

Model |

PHYM4 |

PYWM8 |

PHYM16 |

PHYM24 |

PHYM32 |

PHYM48 |

PHYM64 |

PHYM76 |

PHYM100 |

|

Solution Flow |

1~4 |

2~8 |

3~16 |

4~24 |

8~32 |

12~48 |

16~64 |

17~76 |

20~100 |

|

Mixing Ratio |

3% or 6% |

||||||||

|

Tank Capacity |

0.5、1.0、1.5、2.0、2.5、3.0、3.5、4.0、5.0、5.5、6.0、7、8、9.0、10、11、13、15 |

||||||||

Installation

Device should be installed at places with shelter to avoid sun and rain. Ambient temperature should be within 40°C and leave enough space for operation. Device should be stalled at concrete floor and fastened with anchor nut. Do the hydraulic test after installing. Open the tank exhaust valve first to fill water into bladder from concentrate draining pipe and then close tank exhaust valve when bladder is full. Pressurize the system and keeping for 10 minutes when pressure gets test pressure, tank should have no leakage. Close the water inlet valve and open water outlet and concentrate draining valve to drain water away in bladder. (We will do the test when products leave the factory)

Operating Instruction

1) Add Foam Concentrate

Open the feed inlet when adding foam concentrate and close the water inlet valve and concentrate outlet valve, then add foam concentrate slowly from feed inlet. Do open the bladder exhaust valve if add foam concentrate from concentrate draining outlet. Stop the pump now and then to avoid that bladder burst if air in bladder can not exhaust timely. Foam concentrate should from the same manufacturer and the same type. Close the feed inlet when finished adding foam concentrate. Close the water draining valve (there should be no water flow out this time), tank exhaust valve and bladder exhaust valve. Open the water draining valve 30 minutes later,it indicates that the bladder is undamaged if there is no foam concentrate flow out from water draining valve.

2) Operation of The Device

① Start the pump to supply pressurized water to the device (biggest working pressure is 1.2Mpa)

② Open the water inlet valve and concentrate outlet valve to supply foam concentrate to pipeline

③ Close the water inlet valve and concentrate outlet valve to stop supply foam concentrate when finished working.

④ Keep the pump working to wash pipeline with water and then stop it after that.

3)Maintenance

① To full fill the tank timely after using every time (foam concentrate should be from the same manufacture and the same type)

② Check the surface of the tank and bladder regularly to find out if there are any leakage and corrosion and check all the valves if they work flexibly. Deal with them if there are any problems.

③ Check the foam concentrate regularly to find out if it is deteriorative. Change it if it is.

Related Products

INQUIRY

Winan Industrial Limited

Address: No.17 -1, Fengshun Road, Tongle, Longgang District, Shenzhen City, Guangdong, China.

E-mail: info@winanfire.com

Tel: +86 755 83543133

Fax: +86 755 89906192